Easy handling and high quality at thin sheeting applications,

these are the advantages of the tip ignition procedure

- advatages of the procedure:

- inexpensive welding studs

- 230V AC Schuko connection

- easy handling

- inexpensive studwelder and equipment

- can be easily automated

- no or, depending on the application, only mirroring-visible markings, by the welding procedure, on the opposite side

- painted backsides possible

- Typical applications are :

Control cabinets, vehicle construction, facade technology, cathodic corrosion protection, insulation on metal

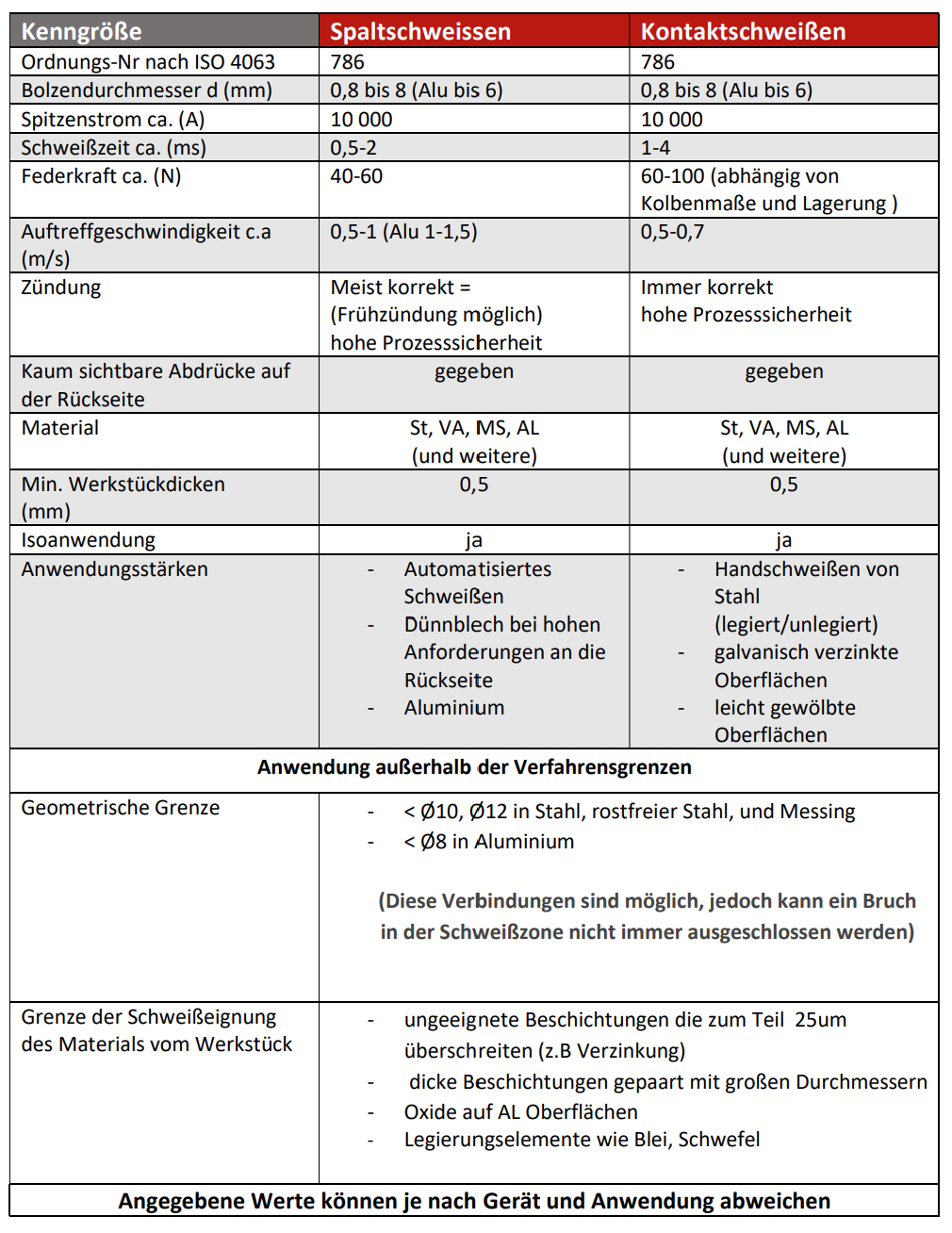

- Types of procedure:

The tip ignition process is divided into the contact process and the gap process. In the following, you will find the two procedures explained in more detail, as well as application strengths and technical details.