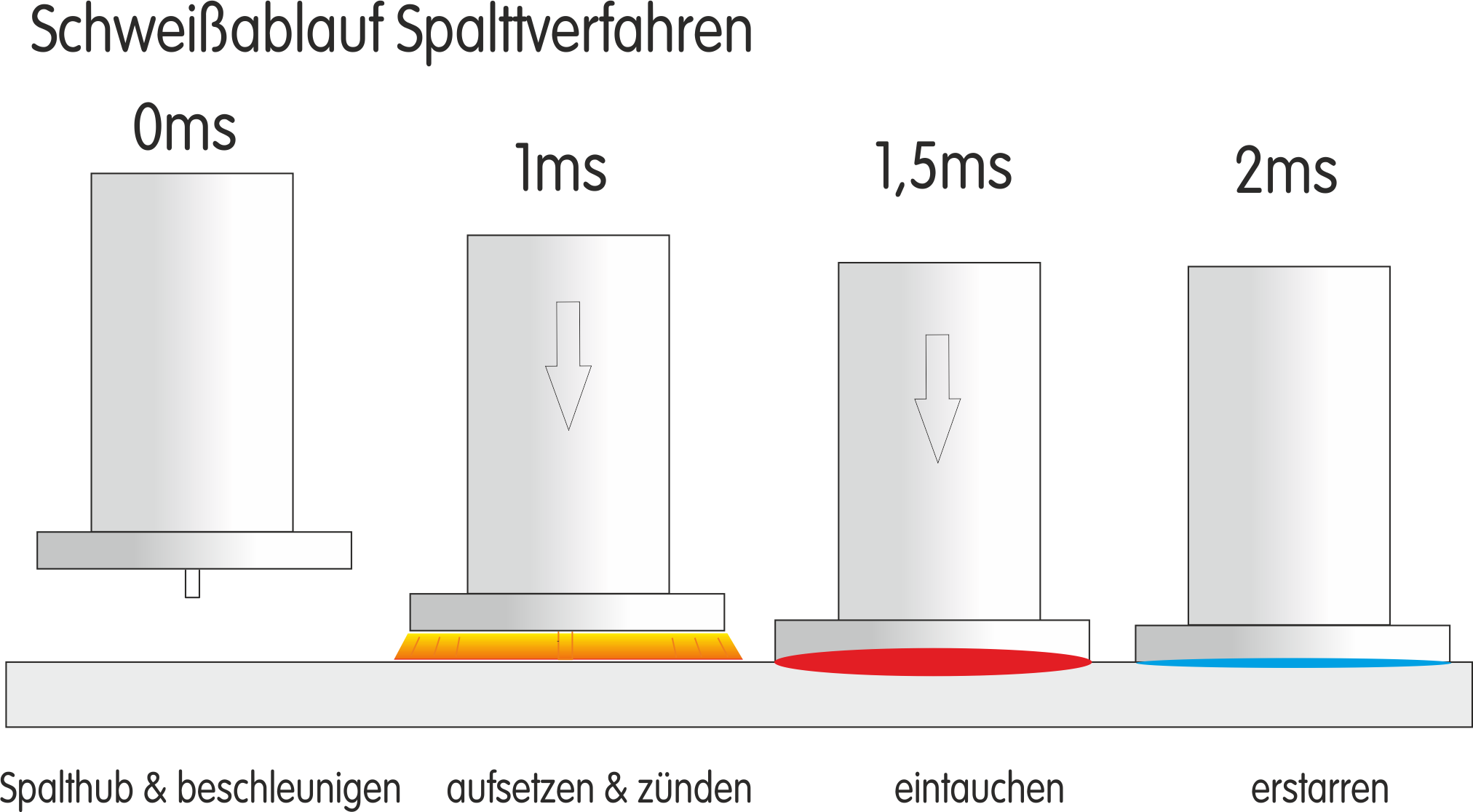

In gap stud welding procedure, the stud is pretensioned against a spring with the help of a magnetic coil. This creates a gap between the stud and the workpiece, which is defined by spacers on the welding gun.

When the operating welder initiate the welding process, the magnetic coil releases and the stud is moved accelerated by the spring towards the workpiece.

As soon as the electrical contact is established, an arc is generated during the forward movement of the stud.

The stud is welded on the workpiece.

applications:

steel, stainless steel, Aluminium

Due to the shorter welding time, the gap process is particularly suitable for steel and stainless steel, as well as for aluminum sheets. Due to the lower joining force, the slitting process is mostly used in automated applications.