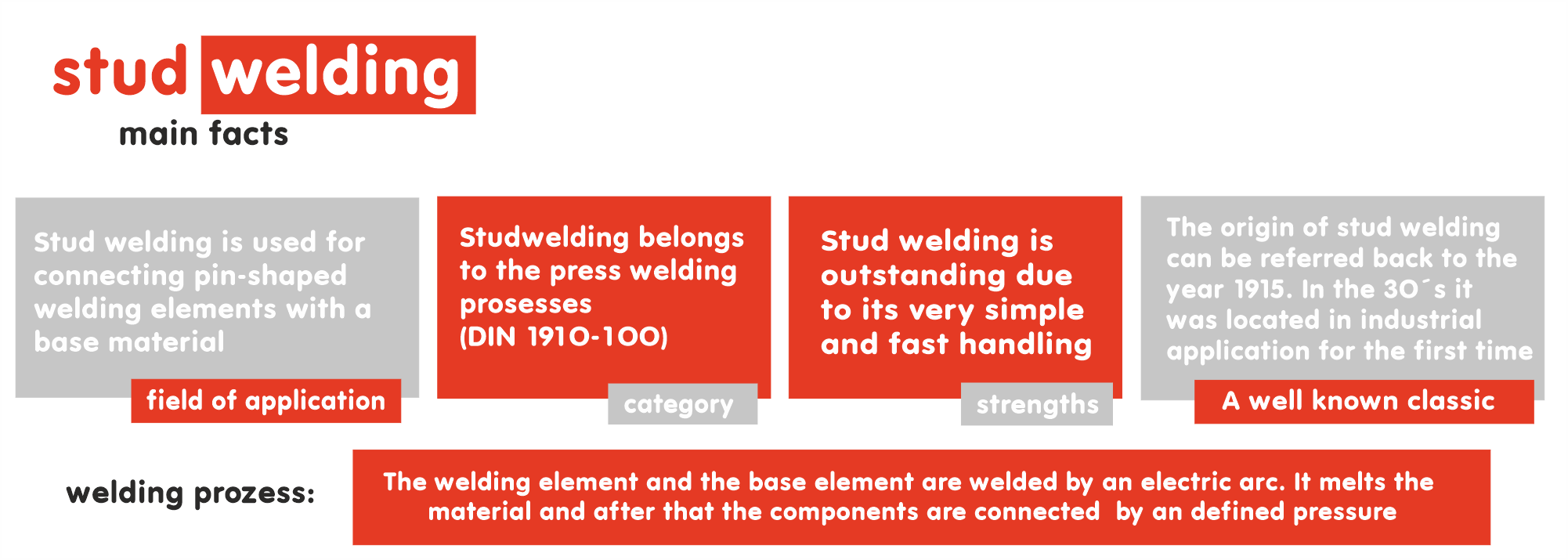

- Where is stud welding applied?

- Wich materials are used?

Today, stud welding is mainly used with: steel, structural steel, high-strength structural steel, stainless steel (V2a), austenitic and ferritic, aluminum, brass, copper, titanium.

Even black - white connections are possible depending on the studwelding process.

- Which welding processes exist?

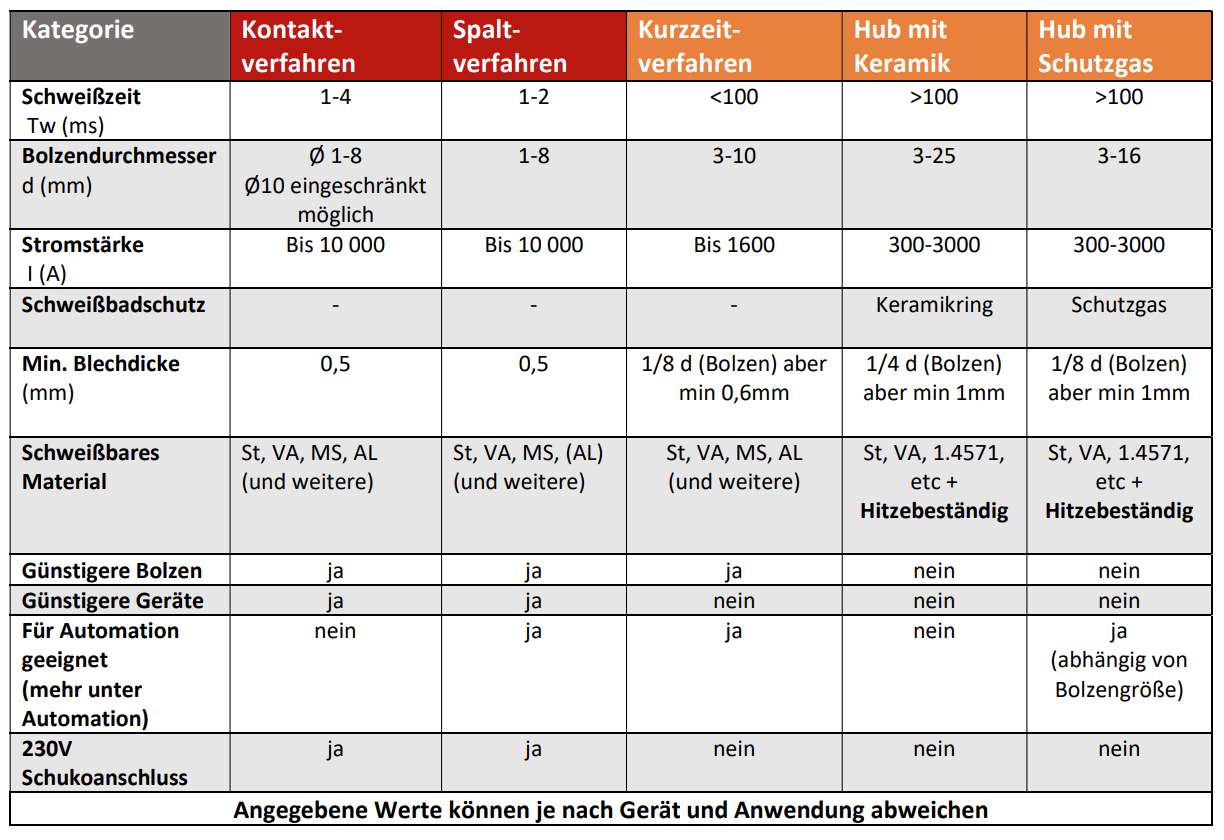

Stud welding is divided in two main processes. CD-studwelding und Arc studwelding. The basic difference between the two procedures is that in tip ignition procedure (CD), the arc is formed over the ignition tip of the studs with a substantially hear welding current and a short time. In the drawn arc procedure (Arc), the stud is lifted to arc length under a pilot arc, and then dips into the molten metal after the welding time has elapsed.

For more information on the processes, see the following links and the associated table. - How efficient is Stud Welding?

With AS stud welders you get welders which already today get along with a minimum of energy use. Because energy is only used in a fraction of a second, stud welding technology is already a process that requires a fraction of the energy compared to other welding processes (electrode, MAG, TIG). The base material is less thermally stressed in comparison to other welding procedures.

The Commission Regulation (EU) 2019/1784 of October 1, 2019, laying down ecodesign requirements for welding equipment pursuant to Directive 2009/125/EG of the European Parliament and of the Council. Therefore this does not apply to stud welding equipment in accordance with Article 1(3) of the Regulation.