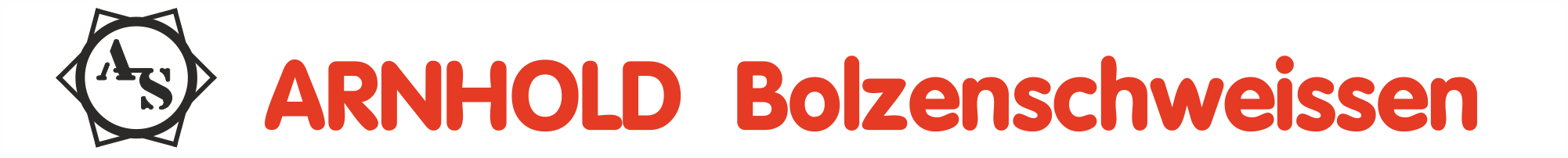

Weld studs offer diffrent mounting options on weldable materials. Weld studs have the advantage that they can provide a stable and hidden mounting option. The types and applications are extremely diverse, so that just about any customer requirement can be met. Our assortment ranges from simple thread studs to internal thread studs, flat plug studs and special applications such as weldable balls.

Tip ignition studs CD / capacitor discharge welding studs

These welding studs can be welded with the studwelder of the AS 1200 or 1266 series. The typical ignition tip provides the stud with its name. As soon as electric current is introduced into the stud, it ignites the arc. Due to the extremely short welding times, these welding studs are optimally used on thin sheets with good surface quality. The welding connection is invisible on the back of the worksheet, depending on the application. The flanged studs can be easily automated.

Our assortment:

|

|

||||

| PT Thread welding studs | UT studs | IT Internal thread welding stud | IS Isolation nails | flatplugs | plate pins |

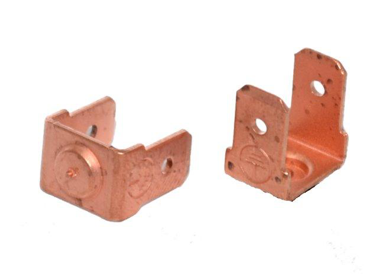

Short cycle welding studs

These welding studs can be welded with studwelder of the AS 21 series or 22 series. Due to the very short welding time, these studs can also be welded on thin automotive sheets. The slightly deeper fusion also allows welding on round or curved surfaces, depending on the aplication. On the back of the workpiece, depending on the thickness, dicoloration may occur. These flange studs can also be easily automated.

Our assortment:

| PS Thread welding studs | US welding studs | IS Internal thread welding studs | Iso pins Ø3-6mm / Clips Ø38 and more |

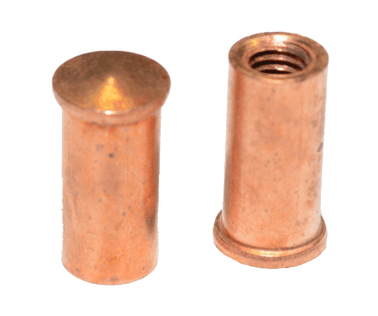

Ceramic ring drawn arc welding studs

Drawn arc studs, with ceramic ring as fusion protection, are used from a minimum stud diameter of 6mm. The main application is in steel aplications and automation constructions. Even studs up to sizes of 22mm weld diameter are possible. An aluminum ball is used from 10mm for fusion soothe. These studs have to be manually positioned and fed. Suitable studwelder can be found in the AS 21 series or the AS 22 series.

Our assortment:

|

|

|

|||

| RD welding studs | PD welding studs | MD welding studs | ID welding studs | UD welding studs | welding studs with ceramic rings |