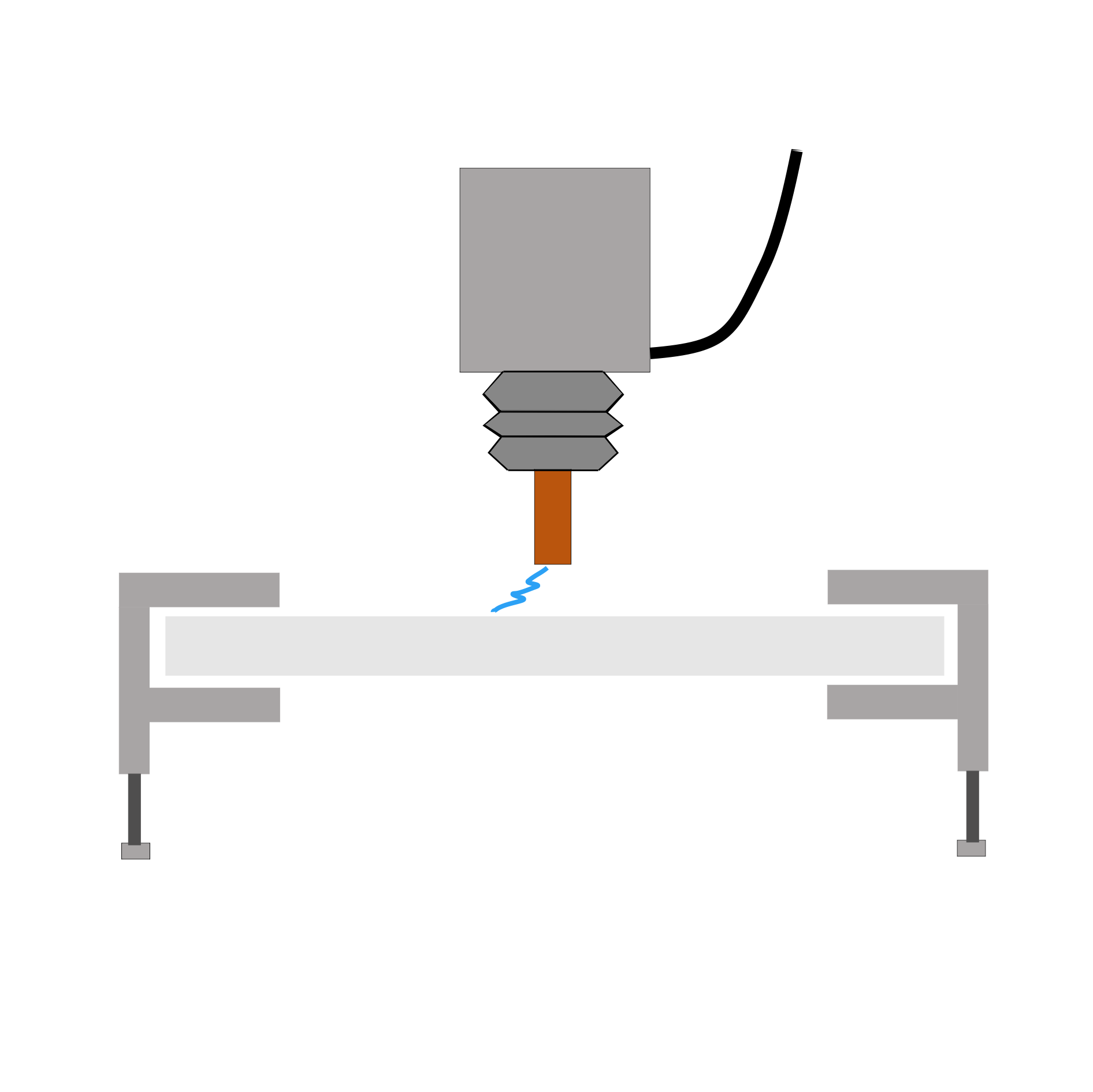

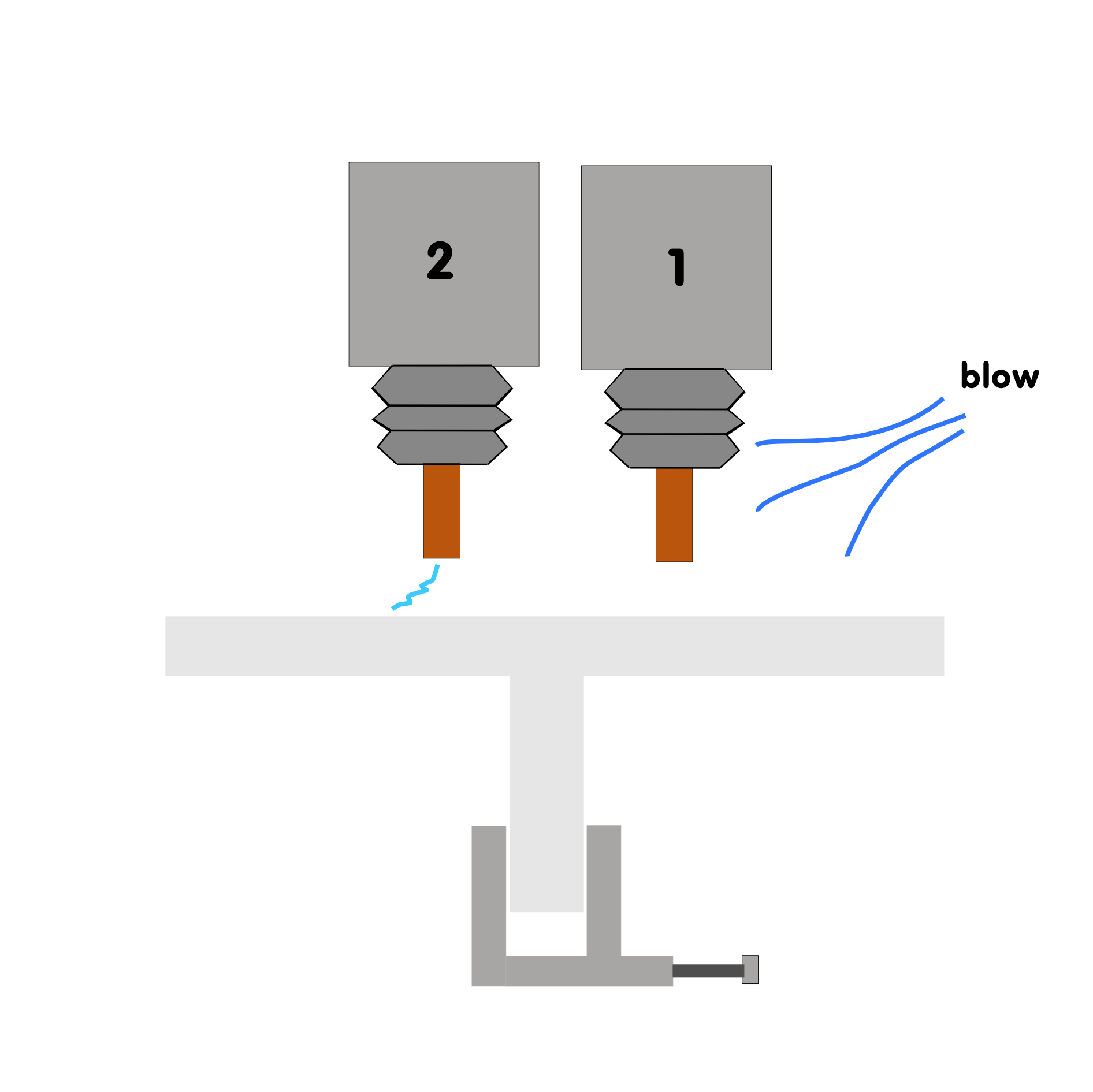

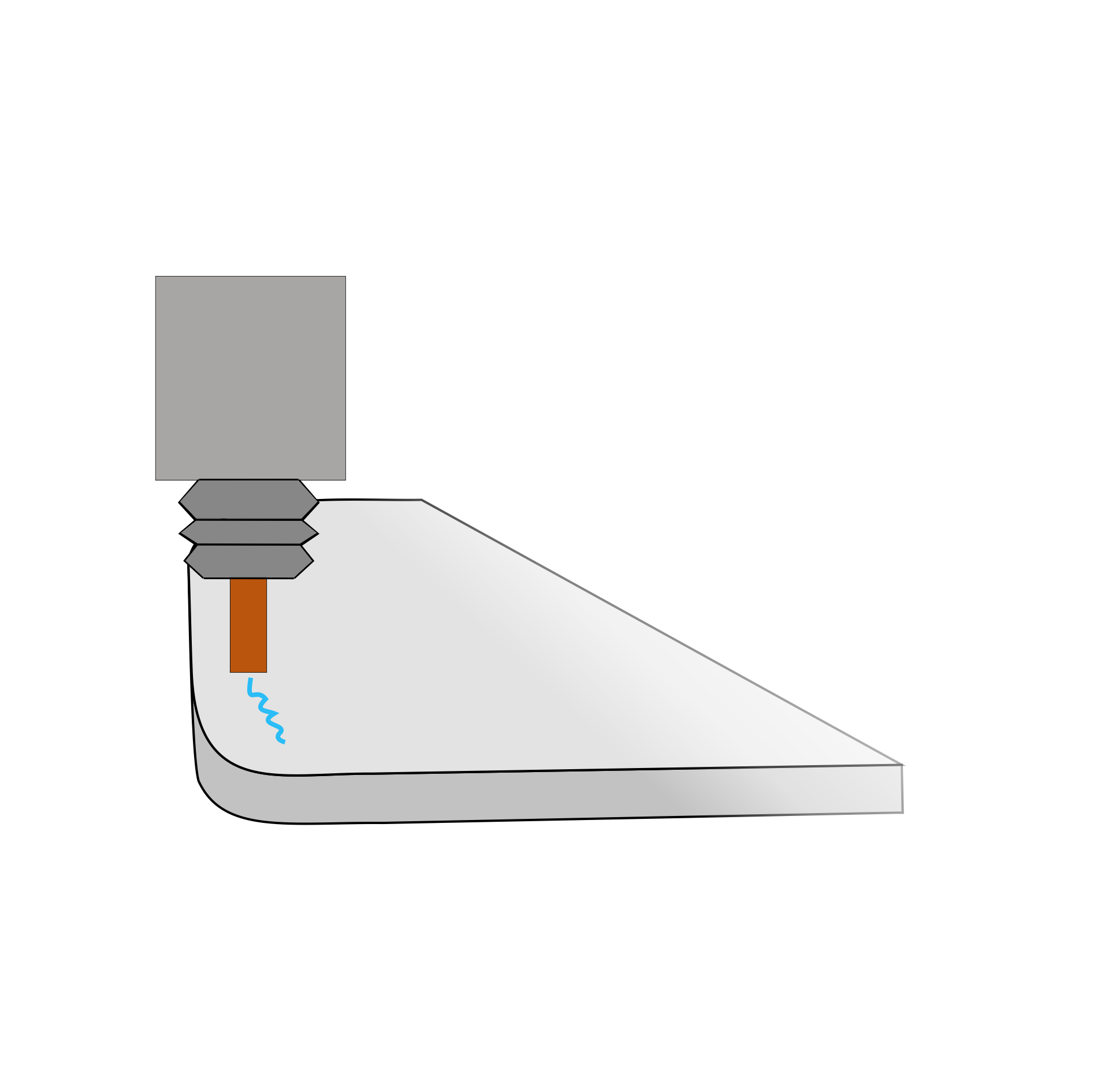

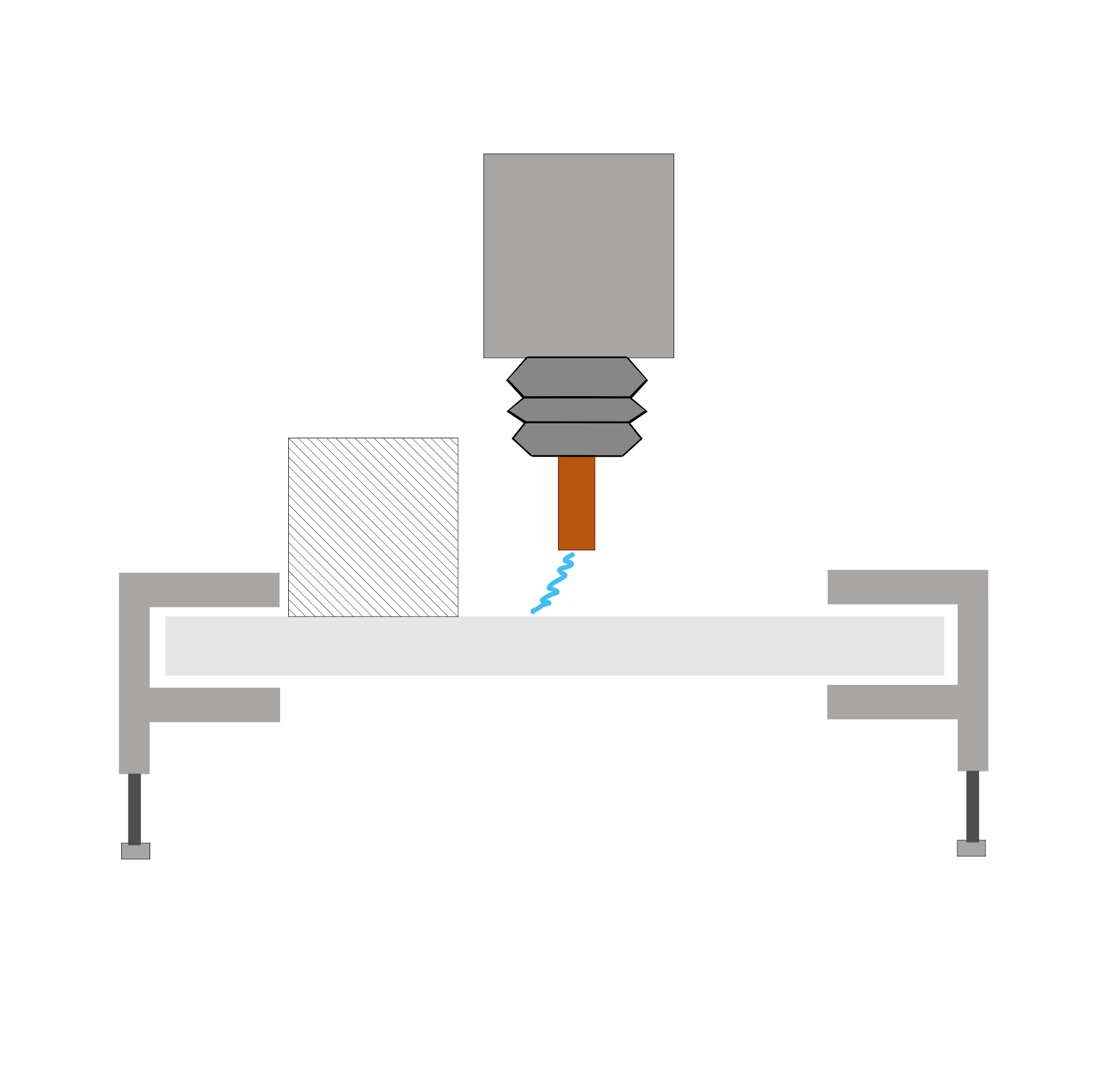

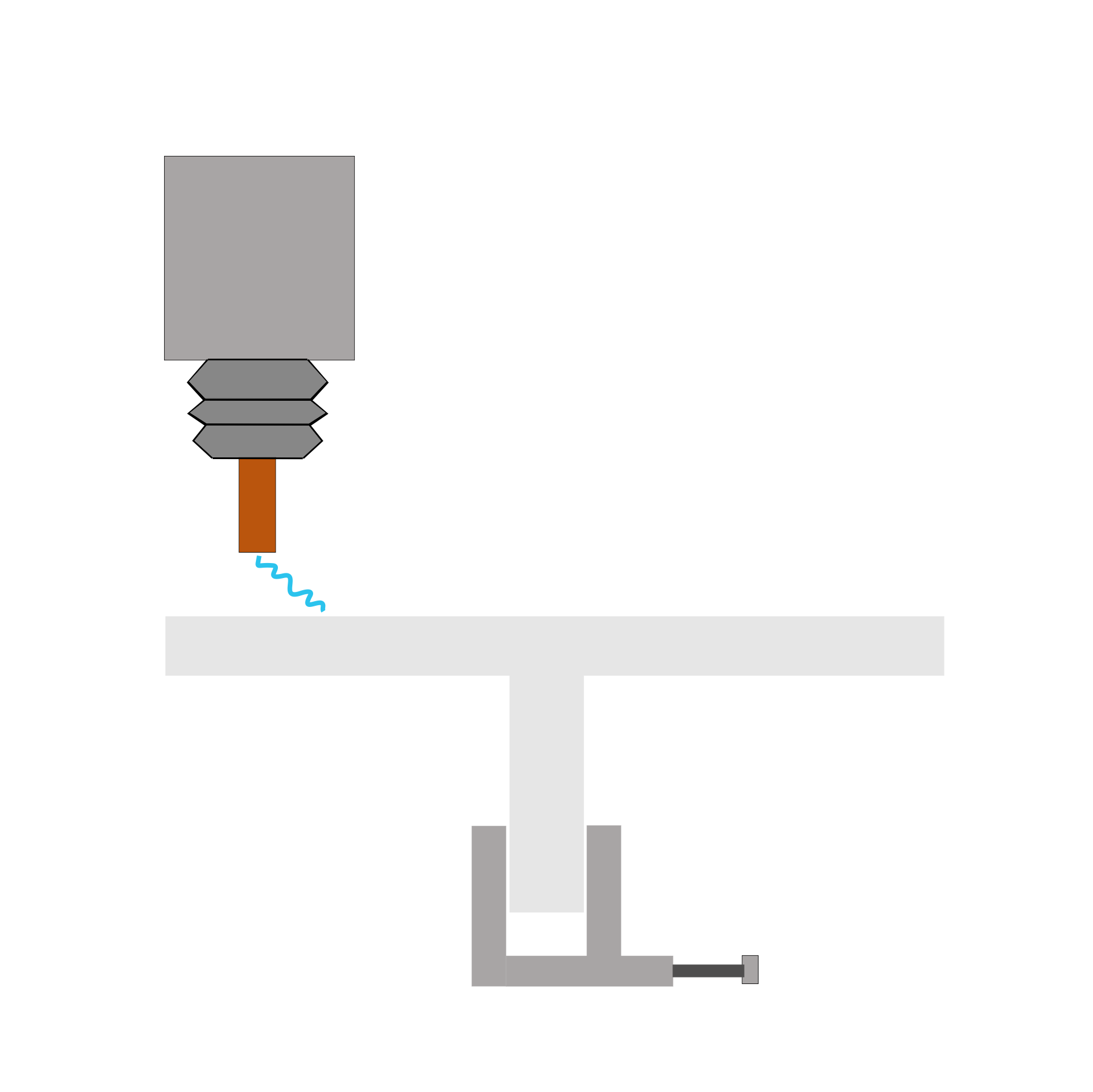

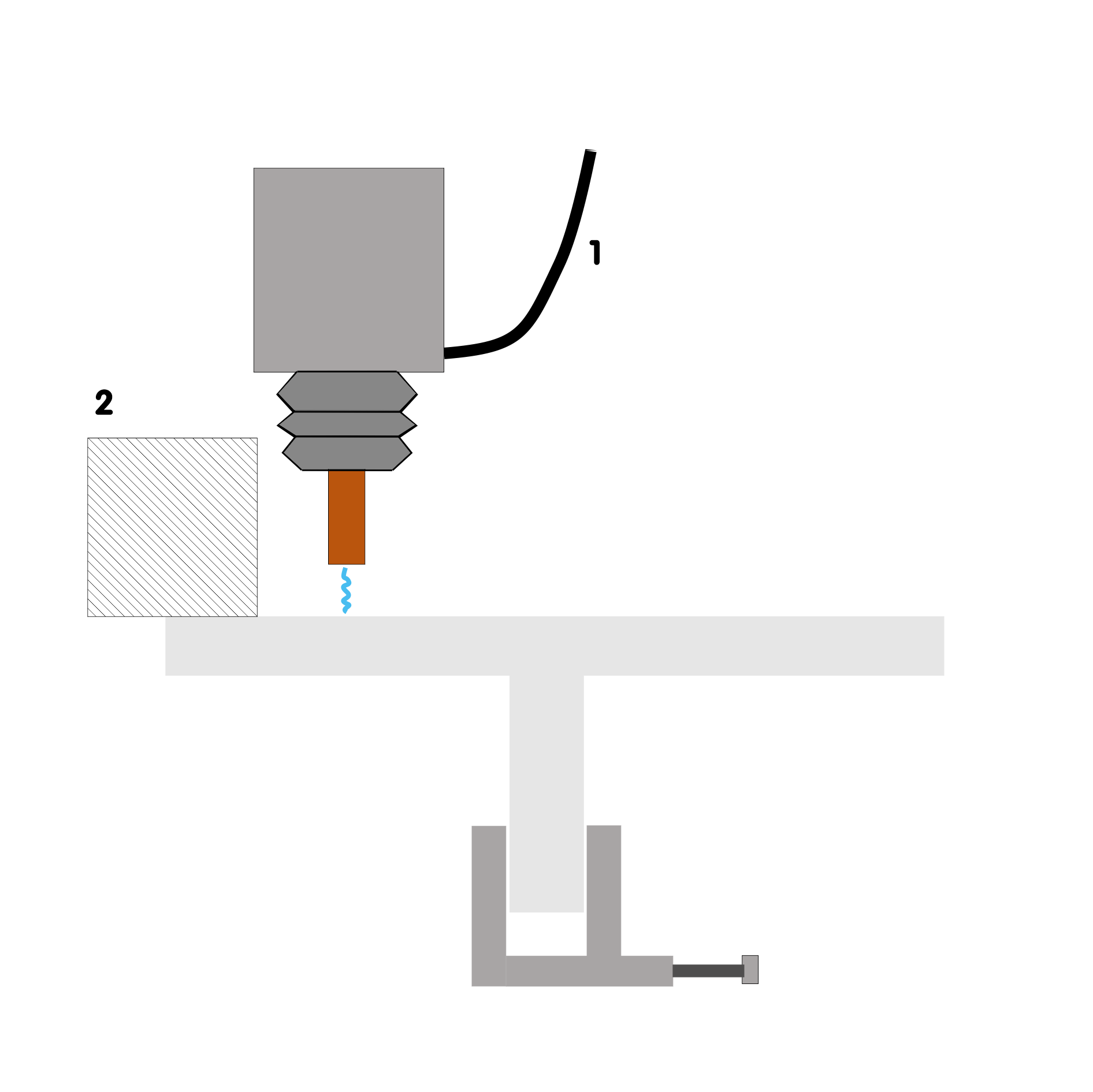

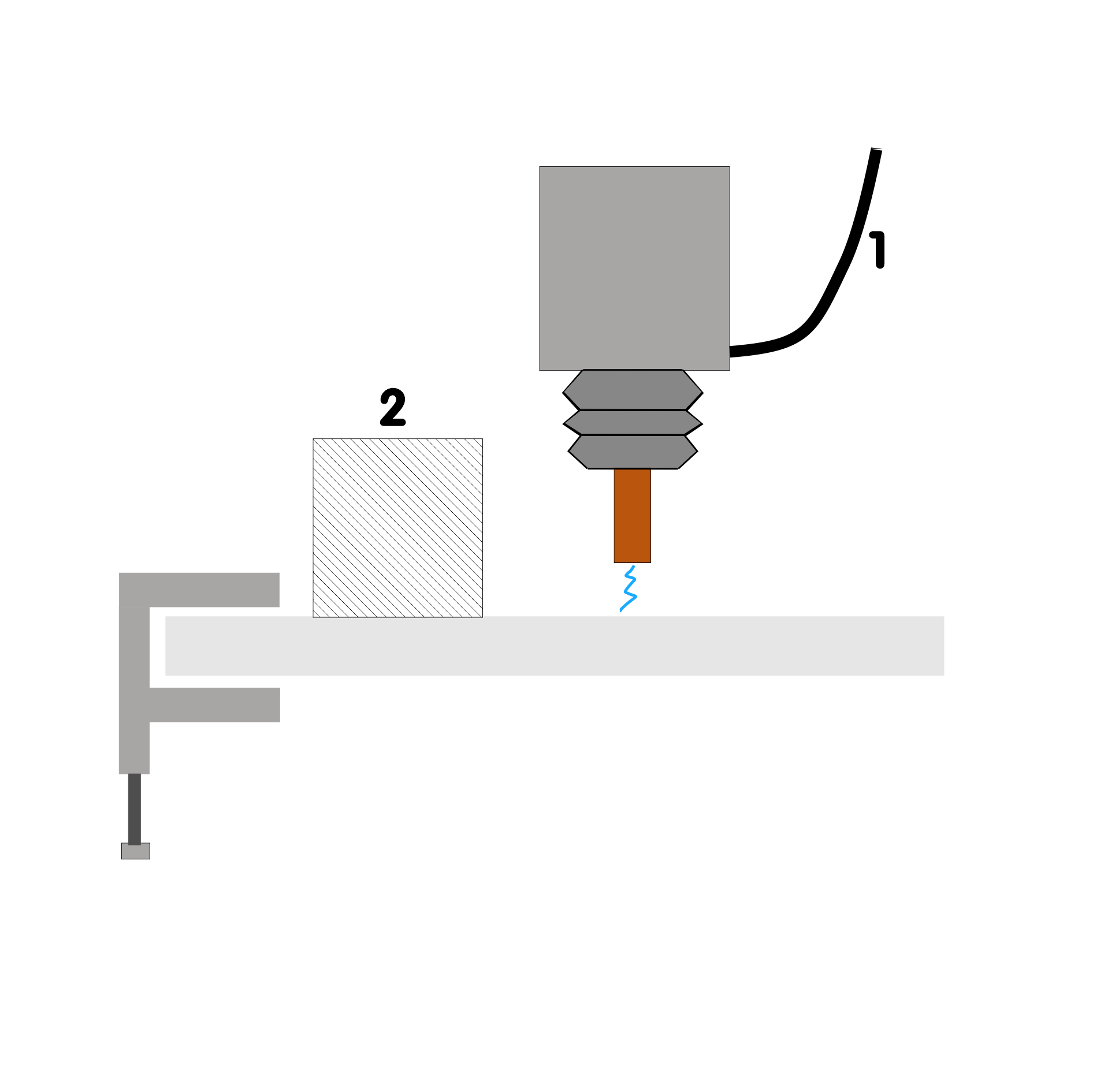

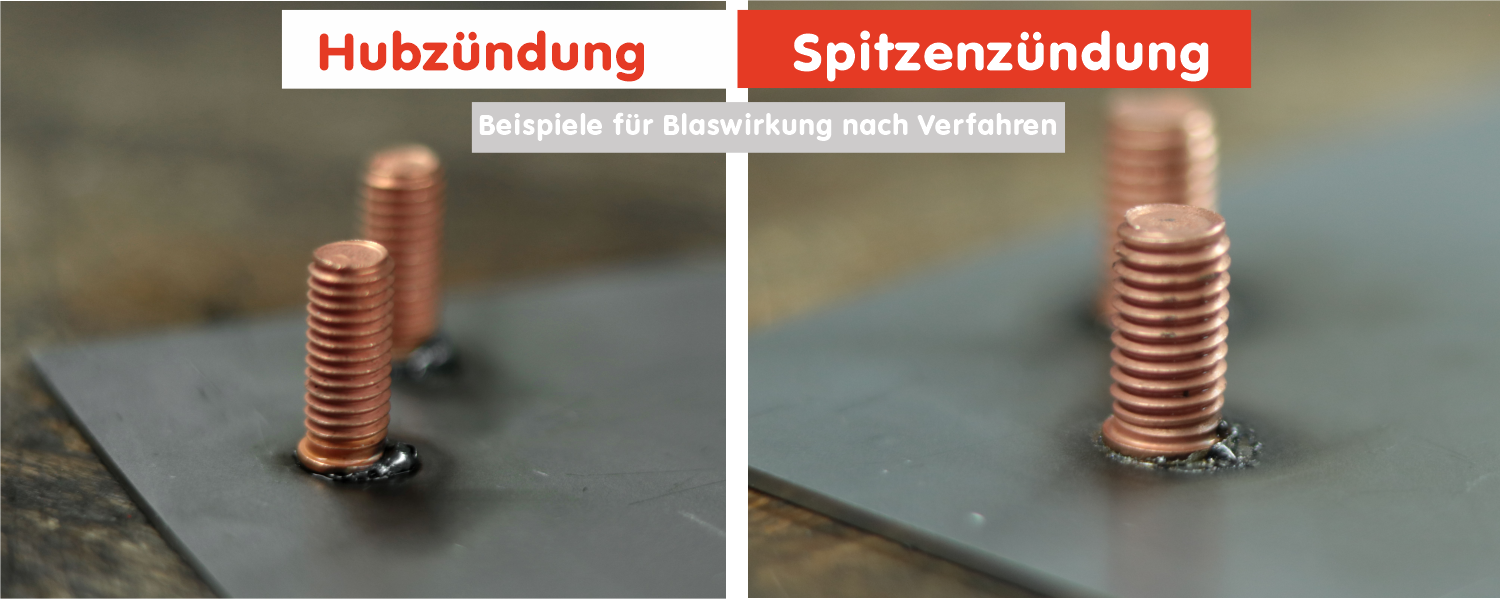

The blowing effect is the one-sided larger appearance of a weld seam on the stud. To achieve a hight quality weld structure, the blowing effect should be avoided in any case.

The blowing effect is reinforced by long welding times and large studs and occurs due to various factors

In the following, you will find the types of blowing effects that can occur and how they can generally be avoided. However, this only serves as a basic overview in order to avoid negligent welding faults and in no case replaces a seminar about the stud welding process. We can offer you such semiars in diffrent topics command about stud welding and about our products on request. In a corresponding training course on blowing effects, we would teach you directly on your specific workpiece how you can avoid blowing effects. You can learn directly in practice to achieve ideal welding results for your application.

Furthermore, our entire stud welding technology and in particular our automation and automation components are optimized through years of experience and practical testing, to avoid blowing effects .