2.3 Alumnium ball and other flux

2.7 Assembly tightening torques for threaded studs

2.8 Strengths of weld stud connections

Technical Information

2.1 Materials

Materials according to DIN EN ISO 13918 are used for all common bolt types. Special materials are conceivable and can be checked by us for availability and weldability. We advise you with pleasure on your welding task.

When placing the order, please inform us whether you require a works or acceptance test certificate according to DIN EN10204 (2.2 / 3.1)

- unalloyed steels 4.8 (similar to former ST37)

Arnhold weld studs are made from steel of strength class 4.8 (DIN EN 898-1) with excellent welding properties. Re ≥ 340 N/mm2 , Rm ≥ 420 N/mm2 , elongation A5 ≥ 15%,

- corrosion resistant steels (A2-50)

Weld studs made of alloyed steels are usually made of A2-50 material (DINENISO 3506-1). Rp0,2 ≥ 210 N/mm2 , Rm ≥ 500 N/mm2 , elongation AL ≥ 0.6d,

Furthermore, the materials A4, A5 1.4571, 1.4401, and 1.5415(16Mo3) are also used.

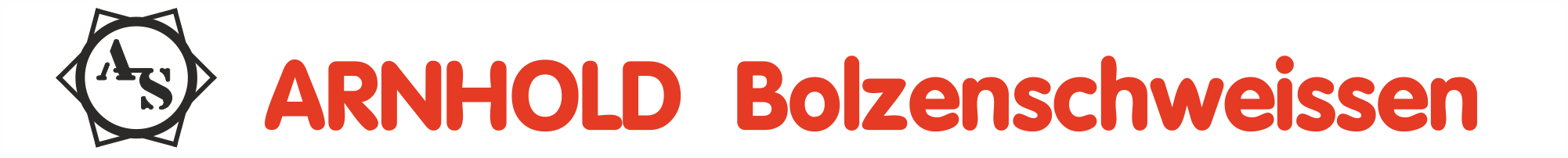

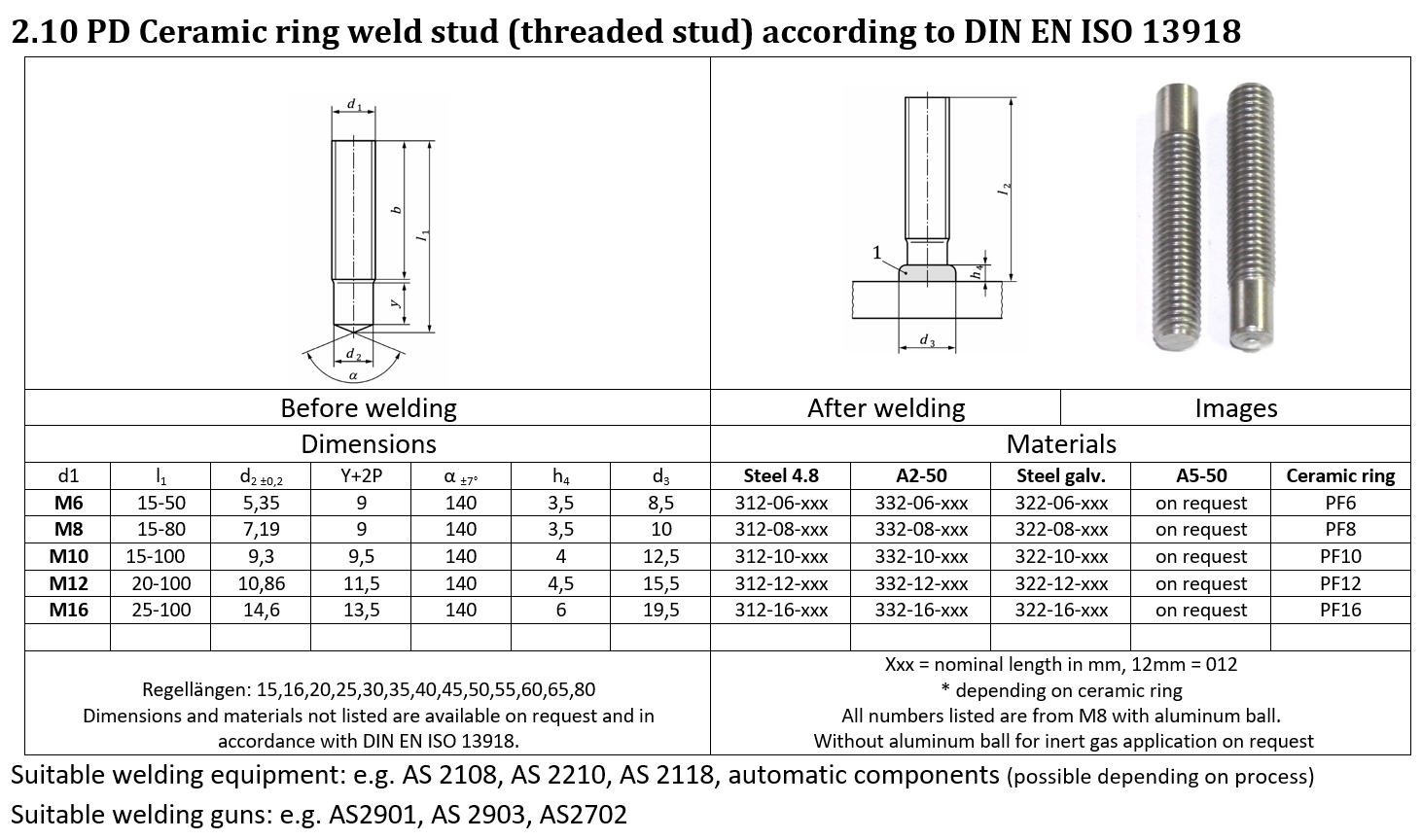

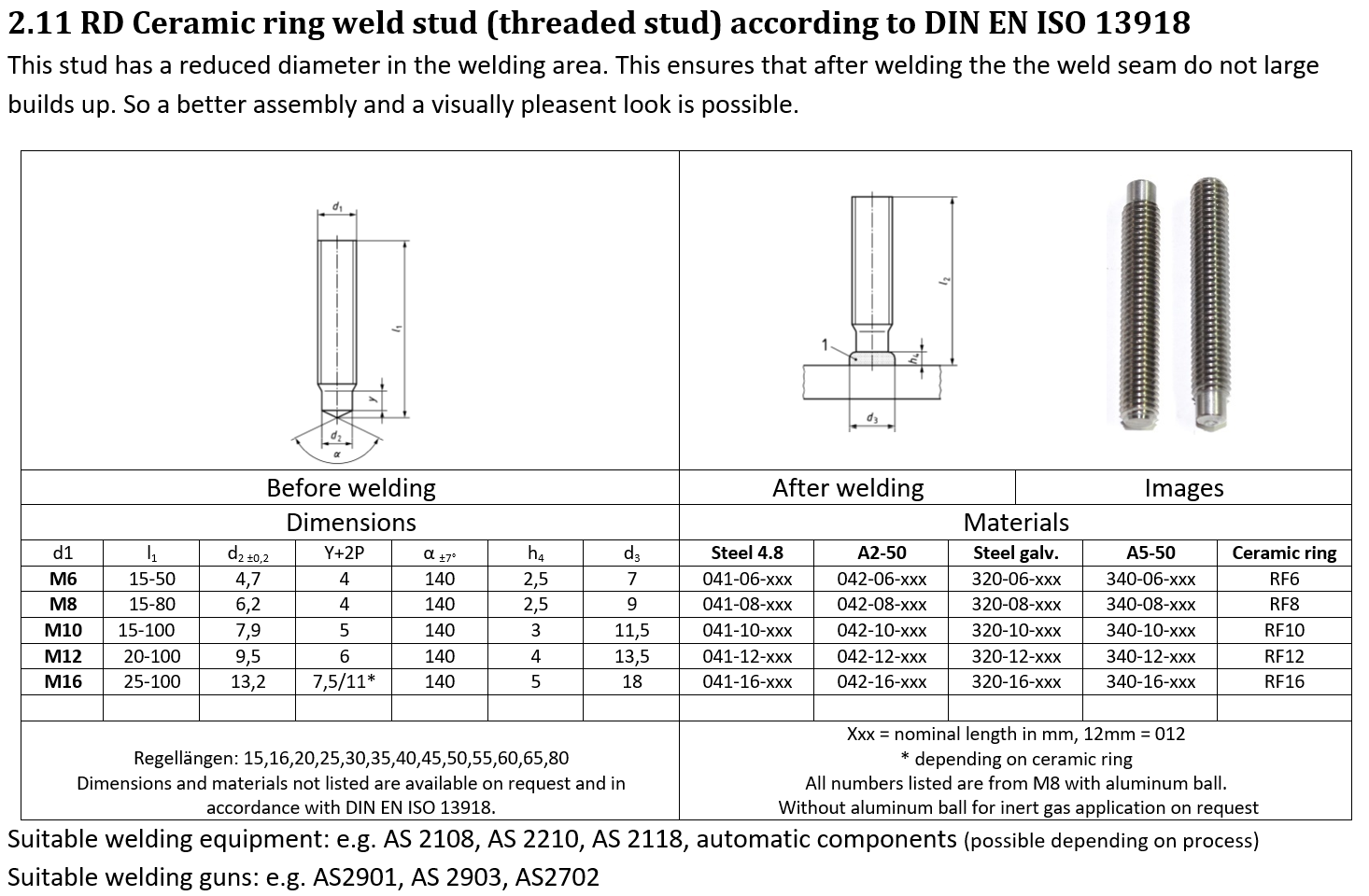

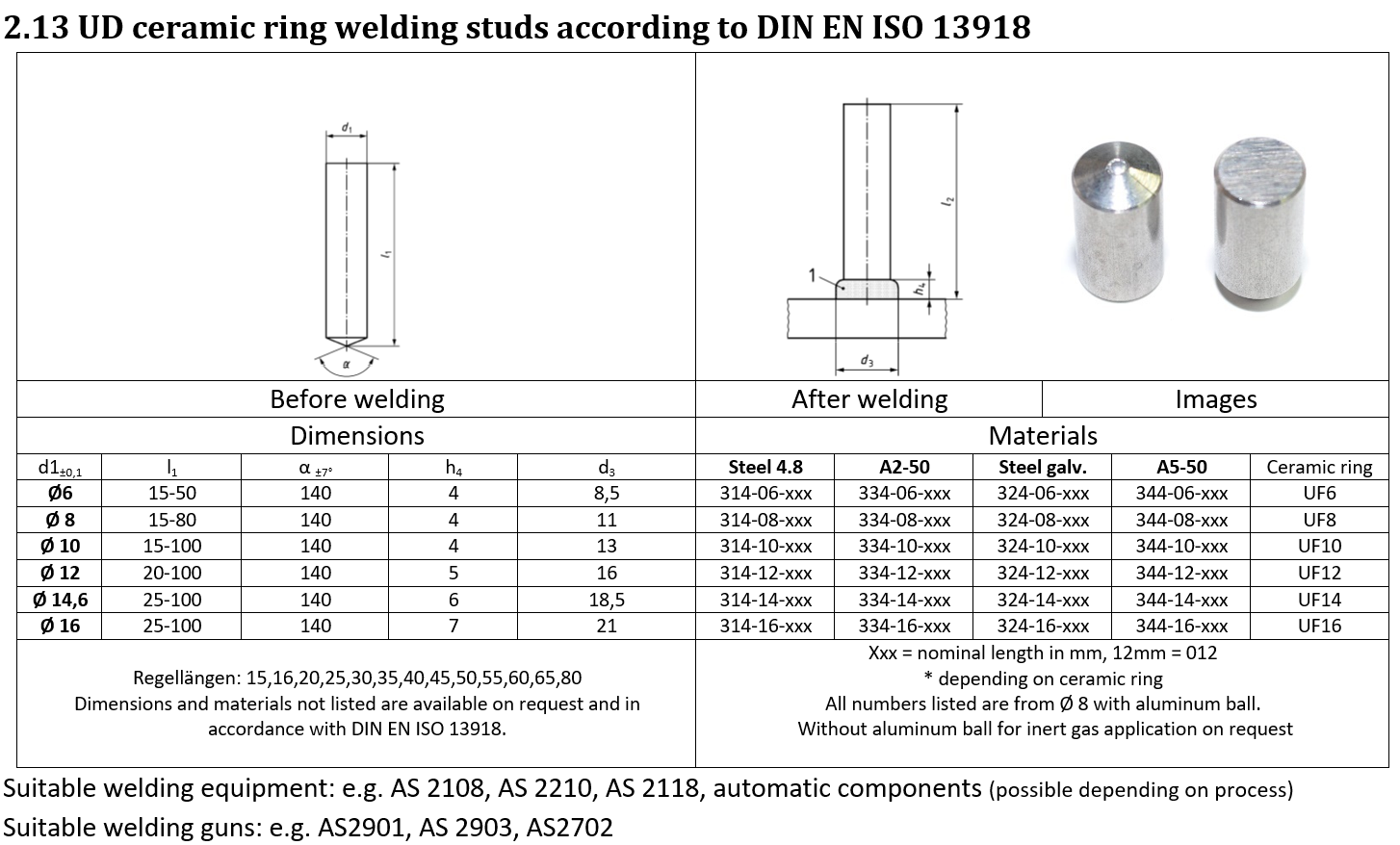

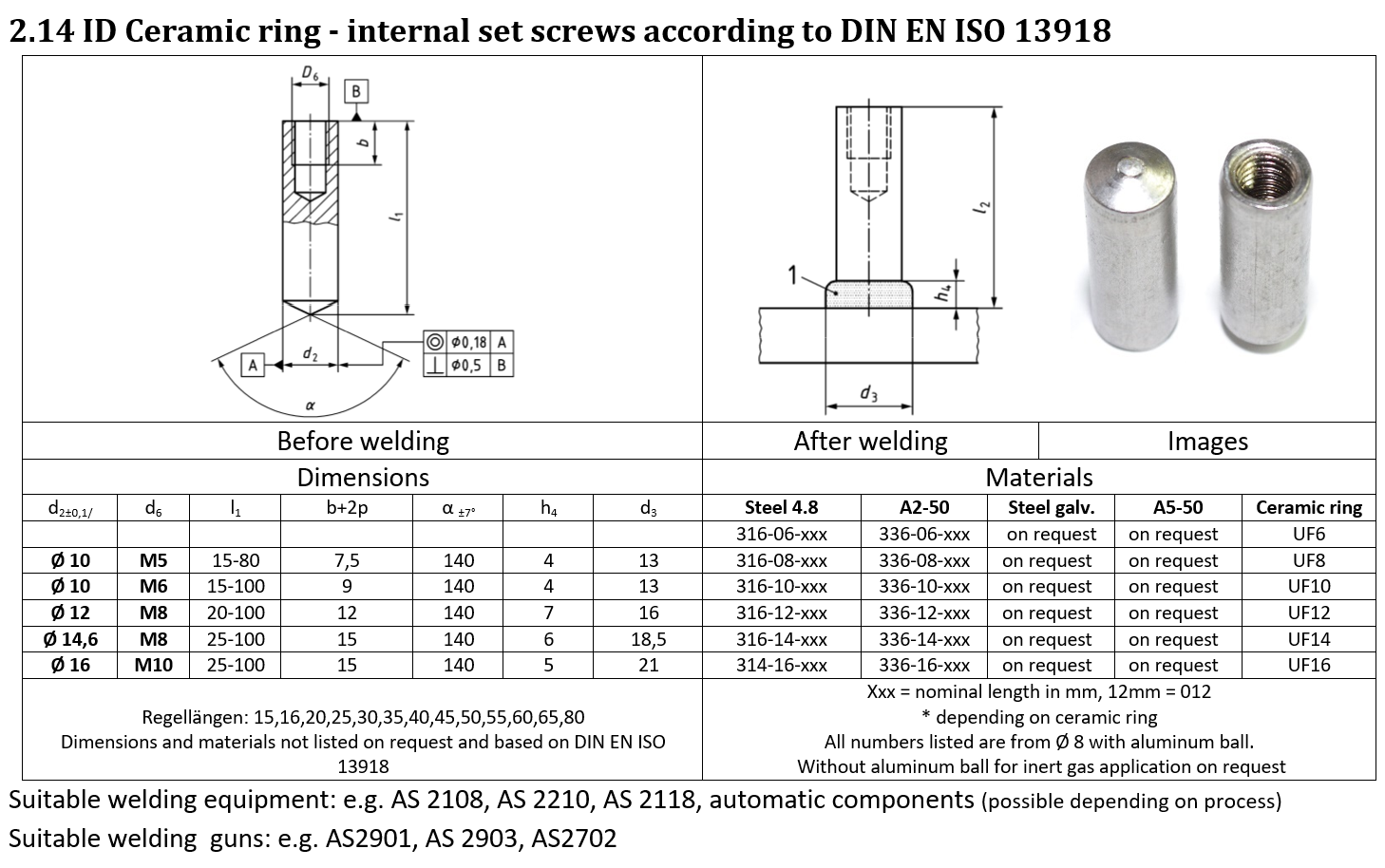

2.2 Dimensions

Please take the dimensions from the corresponding tables for your bolt type. Standardized studs are manufactured according to DIN EN ISO 13918. Dimensions not included and special shapes based on this standard to continue to achieve the best welding results.

Drawn arc studs melt differently during welding. The specified article lengths correspond in each case to the nominal stud length after welding.

The welding allowance of 1 - 5mm is dimensioned so that the stud reaches the nominal length with recommended parameters.

2.3 Aluminum ball and other flux

Weld studs for the ceramic ring process are provided with an aluminum addition in the welding area from a diameter of 6-16. Usually this is achieved by a pressed-in aluminium ball.

Studs up to M10 can also be welded without a ceramic ring under inert gas. In this case, weld studs without a ball should be used to avoid imperfections and improve the flow properties. Under shielding gas, an increased arc blowing effect must be expected. Welds in constrained positions are more difficult.

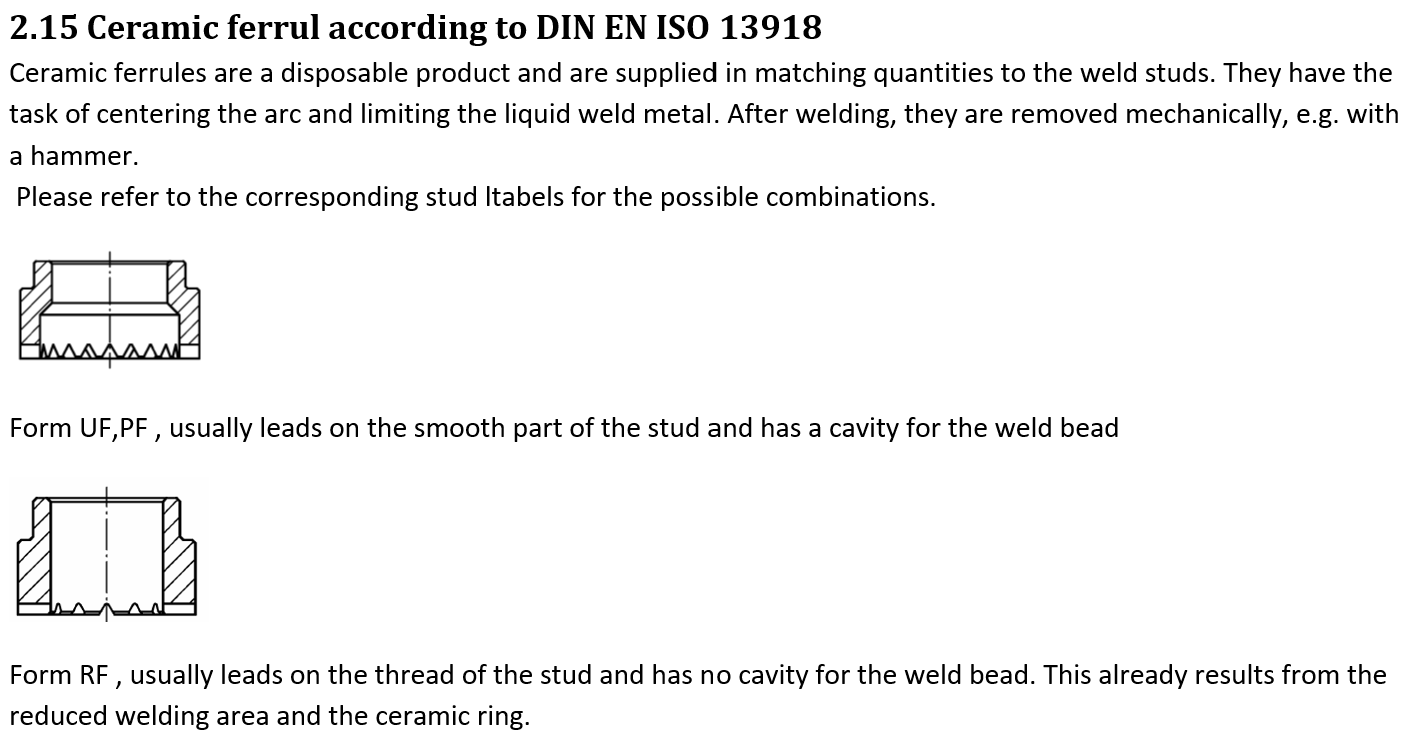

2.4 Melt fuse ceramic ferrule welding

For each ceramic ring stud a ceramic ferrule is supplied, which serves as melt protection. This ceramic ring is supplied in matching numbers with the studs and can only be used once. It is smashed after welding.

Ceramic rings must be stored dry to obtain the best welding results. Re-drying of wet rings is usually not economical or effective.

2.5 Surfaces

Drawn arc welding studs are usually supplied blank.

On request in the surfaces:

- glavanic zinc plated

- electrogalvanized, yellow chromated (not RoHS compliant)

- electrogalvanized, blue passivated (RoHS compliant)

- zinc flake coated

- galvanically copper and nickel plated

- galvanic copper plated

Surfaces 1-4 are mechanically removed after coating in the weld area to improve weldability.

2.6 Thread

The threads are usually cold formed and correspond to tolerance position 6g without surface and 6h with surface.

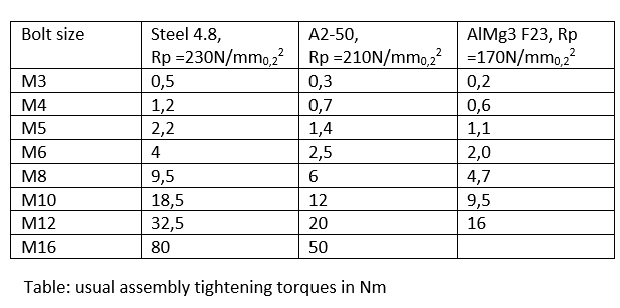

2.7 Assembly tightening torques for threaded studs

The following table shows the minimum tensile force and the minimum torque of a welded joint, without permanent deformation of the workpeace. The requierment is a sufficient thickness of the workpiece material.

The values are valid for threaded studs with standard thread without surface protection and without thread lubrication. Over the entire bolt length, at least the stress cross section must be present (no RD studs). The values apply at the specified yield strengths.The specified values are a recommendation under specified conditions and must be adapted to the actual application.

2.8 Strengths of weld stud connections

Generally, a professional welding assumes that the connection does not fail in the welding. Accordingly, the deformation or fracture occurs in the stud or in the base material. Deviations from this are weld studs with reduced welding range (e.g. mini-flange studs), or unsuitable material pairings, such as black-white connections to be considered differentiated. In case of doubt, the quality of these connections must be verified by a welding procedure qualification test.

The results of the calculation are a stress limit which is defined by the base material or the bolt material with the applied forces. The decisive factor for strength calculations here is the force (tension in the tension cross-section) and the associated material characteristics with a safety factor.