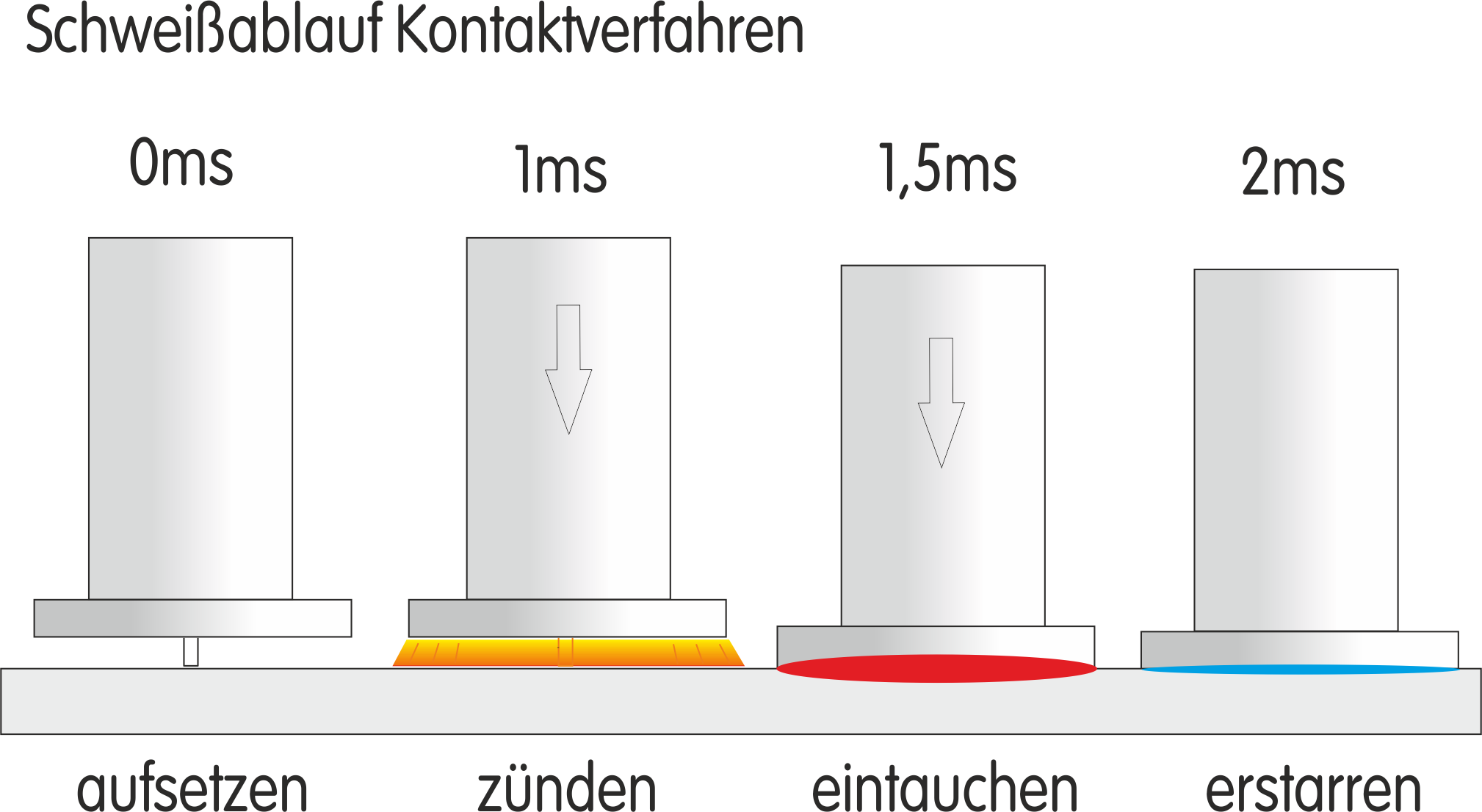

In " contact welding procedure", the stud is pretensioned against a spring when the welding gun or the automatic gun is placed on the workpiece. This results in electrical contact between the stud ignition tip and the workpiece directly from the start.

When the welding is triggered by the welding operator or the automatic system, the ignition tip melts abruptly and ignites the arc between the stud flange and the workpiece.

The stud now moves towards the workpiece, by the distance released by the melting of the ignition tip, due to the spring force. When arriving the final placement of the stud, the fusion solidifies.

Anwendung:

steel, stainless steel, aluminium, brass, metallic coated sheets

Due to the stronger joining force and the longer welding time, the contact process is suitable for steel and stainless steel, as well as for galvanically coated sheets.